Savoring 35 years of Local Flavor- Cape Cod Potato Chips

Cape Cod Life / July 2015 / People & Businesses, Recreation & Activities

Writer: Ellen Albanese / Photographer: Adelynn Boyd and Matt Gill

Savoring 35 years of Local Flavor- Cape Cod Potato Chips

Cape Cod Life / July 2015 / People & Businesses, Recreation & Activities

Writer: Ellen Albanese / Photographer: Adelynn Boyd and Matt Gill

Cape Cod Potato Chips celebrates a big anniversary in 2015

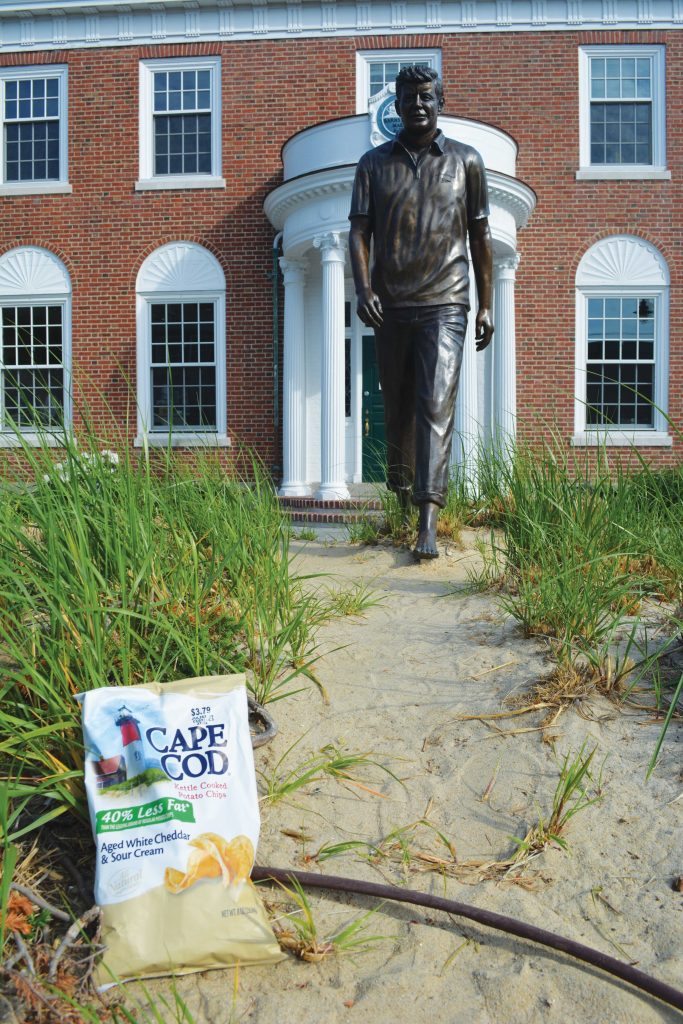

Move over, JFK Museum. Give way, harbor cruises. One of the most popular tourist attractions in Hyannis has nothing to do with Kennedys, or the sea. It’s the Cape Cod Potato Chips factory tour, which draws some 250,000 visitors annually.

This year, Cape Cod Potato Chips celebrates its 35th anniversary. The late Steve Bernard and his wife, Lynn, founded the company on July 4, 1980, in a tiny storefront on West Main Street, where, on a good day, a few employees could produce 200 bags of chips.

Today, the company’s modern factory in Hyannis’s Independence Park employs 100 people across three shifts and is capable of turning out 350,000 bags a day. The chips are distributed to thousands of retailers throughout the United States and Canada.

Steve Bernard was “a real entrepreneur,” his daughter, Nicole Bernard Dawes of Chatham, recalls. “He believed in the American dream. He believed anyone can make it.” Bernard held a series of entrepreneurial jobs ranging from fisherman to forest firefighter before starting the company that would be his legacy.

During the 1970s, Dawes says, while the family was living in Chatham, her mother, Lynn, owned Ardklin Natural Foods in Harwich. Her father was frustrated by the poor quality of snacks available for those who wanted to eat healthy foods. He had read about all-natural potato chips popular in Maui and elsewhere and decided he ought to be able to make them on Cape Cod.

Bernard left his job installing custom car sunroofs and accessories, bought a potato slicer, and launched Cape Cod Potato Chips. Shortly afterward, Lynn joined her husband in his new business, turning the natural foods store over to her sister and co-owner, Darby Ziruk. Ziruk continues to run the business today under the name Organic Market, with stores in Chatham, Dennisport, and Mashpee.

“Everyone thought it was crazy,” Dawes says of her father’s idea. “We had nothing, and now he was risking what little he had on this crazy idea. There was no craft food industry back then, just huge food companies.”

An unfortunate accident on a cold January day in 1981 when Dawes was 8 years old turned out to be the turning point for the business. According to Dawes, a man had a fatal heart attack at the wheel of a car, which subsequently crashed through the front window and into the store, right where she had been standing a moment before. “It’s a miracle I didn’t die,” she says. “My parents had just risked everything—our whole future—on a chip startup. We didn’t have much money. Now there was a car sitting in the middle of the store, glass covering everything. I was 8 and scared. This memory has stuck with me for the rest of my life.”

But because of that accident, Dawes says, her father received some insurance money. On top of that, the accident made the news, and suddenly people were hearing about Cape Cod Potato Chips. “The company made it to the next summer,” Dawes says, “and my parents never looked back after that.”

In 1985, Anheuser-Busch bought the company; a decade later, Bernard bought it back, but sold it to Lance Inc. in 1999. In 2010, Lance merged with Snyder’s of Hanover to become Snyder’s-Lance, one of the largest snack food companies in the country—and the current owner of Cape Cod Potato Chips.

Visitors to the Hyannis plant today can follow the painted seagull tracks from the parking lot to the factory, where they can watch these iconic snacks being sliced, cooked, salted and bagged through a series of windows overlooking the production floor. The tour finishes with a stop in the gift shop, where every available flavor is on sale—along with chip-related paraphernalia ranging from T-shirts to sand toys.

Cape Cod chips come in a variety of styles and flavors. Original, reduced fat, and sea salt and vinegar are the most popular, according to Cheryl Mathias, the Hyannis plant’s retail manager. Some flavors, such as Back Bay Crab, are “limited batch,” meaning the chips are here today, gone tomorrow. New flavor ideas are developed from food trends and even from customers’ suggestions.

One detail that strikes a visitor on the self-guided tour is the amount of hands-on quality control that goes into the potato chip production process. While the gleaming kettles, centrifuges, and conveyors are impressive, significant human intervention is still prevalent at every step. Even before the trucks are unloaded, the potatoes are sampled for density, temperature, size, and defect level, says Lauren Ulrey, brand manager at Snyder’s-Lance. A random sampling of the potatoes in each load is cored, peeled, and then cooked to determine how the potato will chip. From there, the potatoes are peeled with a brush peeler and then inspected by eye once again.

The peeled potatoes are sliced and lowered into long, rectangular kettle fryers. When the chips reach a precise golden brown color, they are taken from the kettle and placed in a centrifuge where the excess oil is spun off. (To make the brand’s reduced-fat version, the chips stay in the centrifuge longer to spin off more oil.) The freshly cooked chips are again inspected by hand, then salted and packaged.

The Cape Cod difference is kettle cooking in small batches, Mathias says. In the company’s large rectangular kettles, the oil is turned continuously by rotating mechanical “rakes.” Visitors can watch as a batch of potatoes is sliced and dropped into the kettle. When the potatoes are done, they are turned onto the centrifuge. That leaves the kettle momentarily empty, which allows the oil to reheat to the proper temperature before another batch drops in. This is different from a “continuous cooking” method, where chips move through the oil continuously with no breaks, Mathias says, and it’s what makes Cape Cod Potato Chips so crunchy.

Each week, some 750,000 pounds of potatoes are cooked into 190,000 pounds of chips, Mathias says. And the process is quick: The time between off-loading potatoes and sealing chips in bags can be as little as 20 minutes.

The company works with potato farmers from Maine to Florida, moving down the coast to follow the annual harvest. The farmers grow “chipping potatoes”—various varieties of white potatoes that offer a high yield, low water content, and low sugar.

Steve Bernard’s snack food career did not end with Cape Cod Potato Chips. In 2003, he and his daughter launched Late July Organic Snacks and ran the company together until Steve’s death in 2009. After a decade based in Barnstable, Late July is now headquartered in Boston. Dawes continues as the company’s CEO.

“I was incredibly lucky to have my dad as a mentor,” says Dawes. “He didn’t hide any aspect of the business from me when I was growing up. He shared the good and the bad.”

Even today, Dawes says, seeing Cape Cod Potato Chips on store shelves is “a way to say hello to my dad every time I’m in the supermarket.”

For more information about the company, visit capecodchips.com.

Ellen Albanese is a freelance writer who lives in Waquoit.